Rethinking Airport Terminal Design to Achieve Net Zero Impact

4 Strategies — Including Innovation from Other Building Sectors — to Implement Measurable Solutions

By Josh Greenfield and Kevin Ashton

The United Nations estimates that the global aviation industry accounts for roughly 2% of global carbon dioxide emissions. Most of this impact is from jet fuel emissions, but terminals and their operations are a measurable part of the picture.

The Federal Aviation Administration and the International Air Transport Association have set out ambitious sustainability goals that airports around the world have signed on to support, through efforts such as the Airport Carbon Accreditation program. These goals range from reducing greenhouse gas emissions and using electric vehicles to developing sustainable aviation fuels and efficient aviation infrastructure — including terminal buildings. Carbon neutrality focuses on limiting carbon dioxide equivalent emissions and offsetting the emissions produced to achieve “neutrality” whereas net zero encompasses reducing all carbon dioxide equivalent emissions to as low as feasibly possible prior to on-site or off-site offsets; both must be addressed for airports to achieve sustainability goals.

Airports aiming for net zero will require both proven solutions and ideas from other building sectors. Facilities whose building envelope and systems use sustainable design approaches will begin with principles that are applicable to any building: using the local climate for passive heating/cooling, reducing internal zone loads via analysis-driven façade selection, and optimising mechanical, electrical, and plumbing systems’ efficiencies and control sequences. Then when applied to an airport terminal, an integrated approach takes advantage of features such as terminals’ large volume spaces, sprawling sites, and travelling and working occupants.

Net Zero Terminal Lessons: Proven and Innovative Solutions

A forward-thinking approach to terminal design is most effective when we draw on best practices both from airport terminals and other building types that:

- Optimise form and function to deliver aesthetic results with minimal impact

- Specify carbon sequestration techniques and sustainable materials

- Reduce energy loads through building system design choices

- Use renewable energy sources

1. Optimising Form and Function

People often spend as much time in the airport as they spend flying, so the environment in the terminal drives passenger satisfaction and is a key consideration for this approach. Moreover, terminals are the workplace of hundreds of people whose needs aren’t always fully considered.

Moving toward net zero begins with orientation on the site and organising the space. Whether the terminal is large or small it is usually sprawling and low, typically ranging from one to four stories. Aircraft requirements — how many, how big — drive the mass and form. But within those constraints, there are opportunities for reducing carbon footprint. Solar angles are predictable, and using solar geometry to rotate a building, or offset a glazed wall by only a small, calculated angle, can reduce solar transmission.

Incorporating biophilic design features that bring in nature can also further net zero goals and improve aesthetics. Human-centred design strengthens the relationship between the built space and the people in it; connecting both airport travellers and staff with nature provides a sense of place, is socially responsible, and improves the customer experience. For example, Pittsburgh International Airport’s Terminal Modernisation Program will include four outdoor gardens along with a "green spine" with landscaping and art installations in front of the terminal building.

Clean air is a big concern in an airport terminal so designs that block engine exhaust or otherwise clean the air prior to taking it into the terminal will promote well-being, particularly in areas where airport employees work. Building systems can use advanced filtration efficiencies and low/no ozone producing bipolar ionization technologies. Green/living plant walls offer innovative opportunities in airports for cleaning air and drawing travelers into nature. The U.S. Green Building Council promotes including horizontal vegetated spaces, such as outdoor terraces, to accrue LEED points.

Public spaces for travellers typically have high ceilings, natural light, and lots of windows because travellers want views of airport operations around them. But large spaces and glass walls work against net zero in building systems. Thankfully, high performance triple-glazed window systems, dynamic glazing based on electrochromic and/or thermochromic technology, and exterior shading features can all lower the solar transmission and conductive gains/losses of a highly glazed envelope, while providing the increased window-to-wall ratios that airport travellers have come to expect.

Often airports feel they can’t afford the initial investment in high performance window systems. But consider this example from Dallas Fort Worth International Airport, which decided to invest in dynamic glass for the Terminal A building. This resulted in lower temperatures in the gate lounges and reduced the energy needed for air conditioning in the space.

Courtesy Dallas Fort Worth International Airport

An unintended positive outcome was that more people remained near the gate areas outfitted with the dynamic glass, and sales at concessionaires within that area increased by more than 100% (month-over-month for more than one year). So, this sustainable decision created a win-win-win: reduced energy consumption, improved customer experience and improved business performance. Taking a life cycle view can yield long-term cost savings that may not quite be net zero or LEED Gold but trend in the right direction.

2. Carbon Sequestration and Sustainable Materials

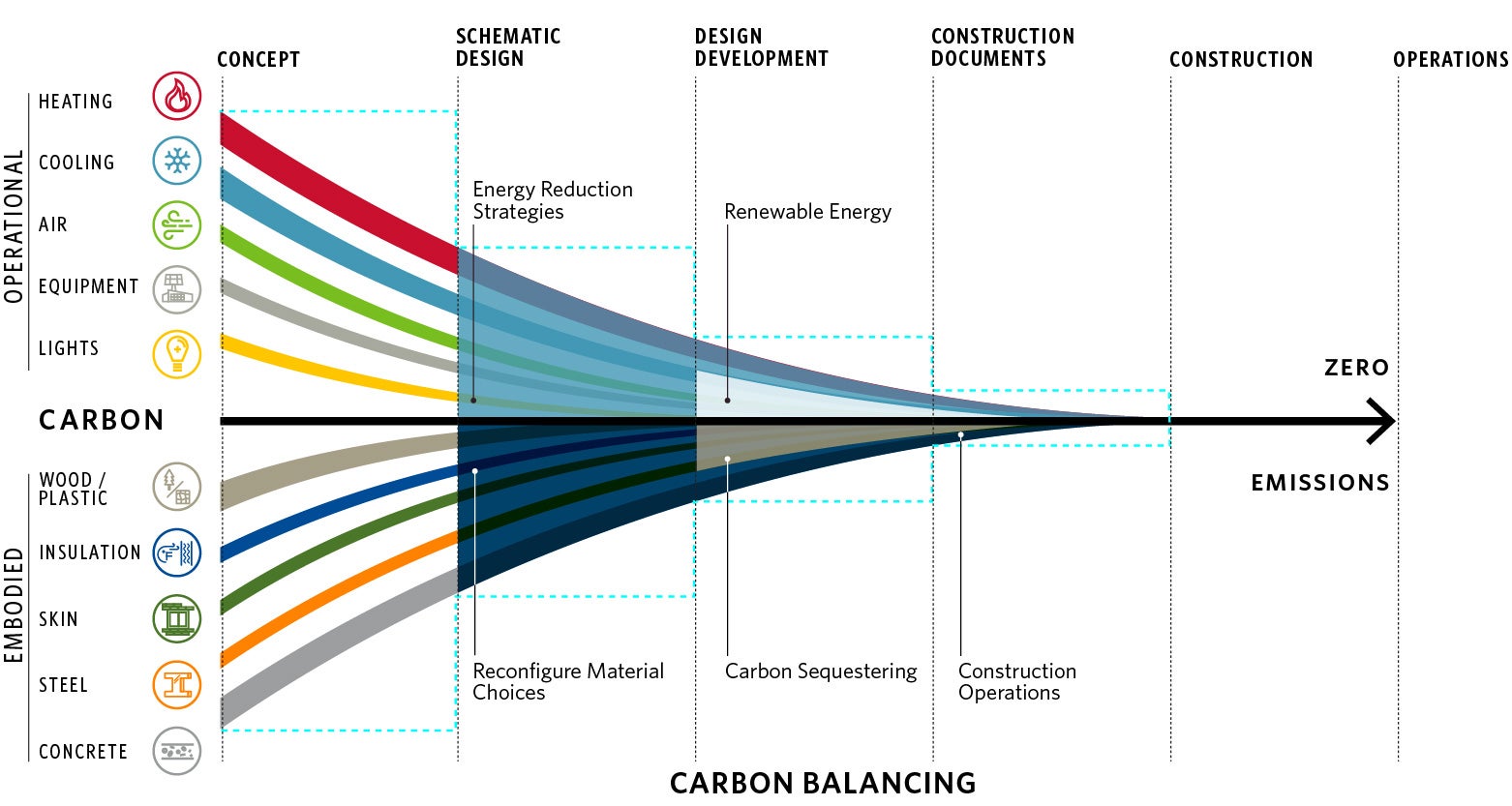

Concept planning for a net zero terminal begins with recognising the two major contributors of carbon: construction materials and operational choices. Carbon sequestration techniques capture and store carbon dioxide in lieu of it going to the atmosphere. Embodied carbon represents the carbon emissions released during the lifecycle of building materials, including extraction, manufacturing, transport, construction, and disposal. Choices about materials that come from embodied carbon — wood and plastic, insulation, steel and other components — drive initial construction cost. Operational implications such as requirements for heating and cooling and demands of equipment impact a facility’s carbon footprint and total life cycle cost.

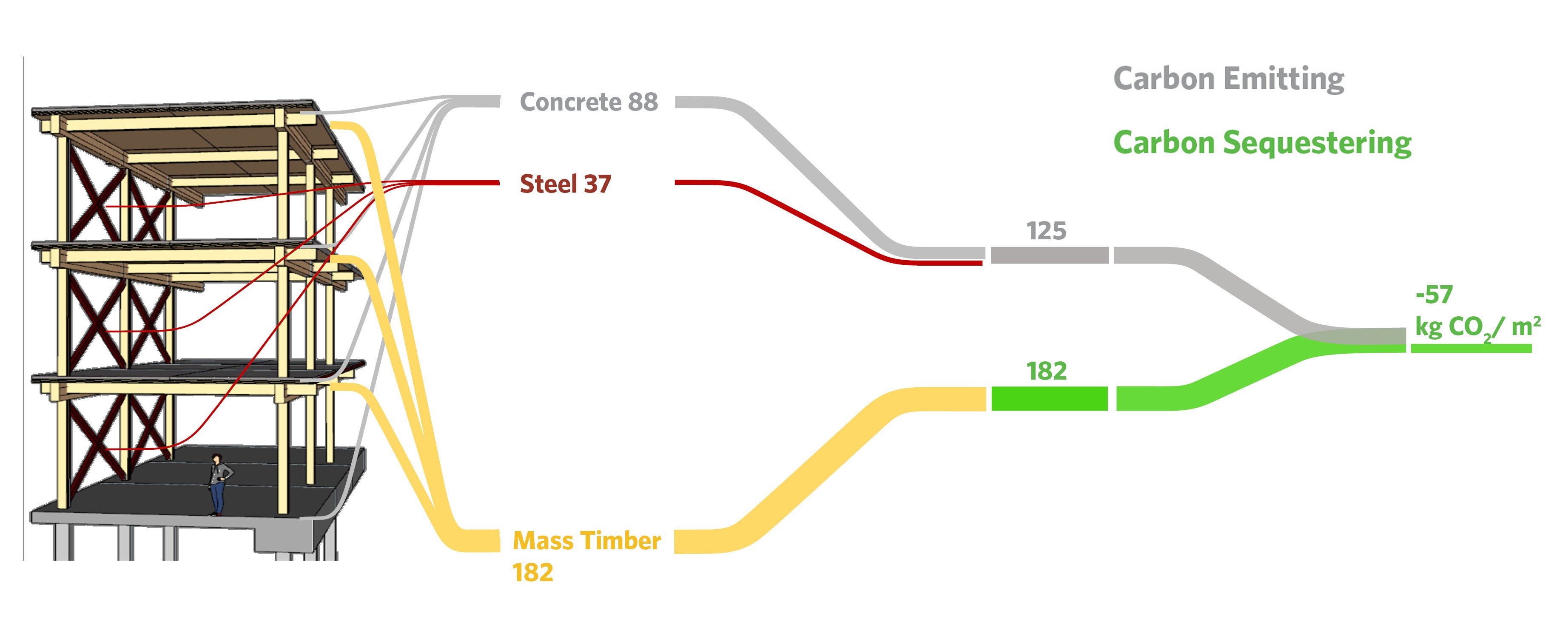

More airport terminals are incorporating wood into their designs, and mass timber is big — it’s the anti-steel. Portland International Airport recently completed a terminal makeover that included an 18-million-pound mass timber roof. This strategy has been used in non-aviation buildings such as the headquarters of the Orange County Sanitation District that HDR designed in California, where a hybrid mass timber design with expressed steel-braced frames is under construction, planned to achieve LEED Gold and ILFI Zero Energy certification. Mass timber manufacturers are found throughout the United States, which is important because “embodied carbon” considers the travel distance between the source, the manufacturer and the project site.

Often the biggest carbon expenditure in structures is concrete. The process for manufacturing cement, the all-important glue that binds concrete, accounts for roughly 8% of the world’s anthropogenic carbon dioxide emissions, according to the International Energy Agency. Replacement ingredients in concrete can make it more carbon friendly, such as fly ash or ground granulated blast furnace slag, to reduce the carbon intensity. CarbonCureTM is a useful process which injects carbon dioxide as concrete is produced, using existing manufacturing operations; this approach allows owners and contractors to benefit from carbon sequestration using existing trusted concrete suppliers rather than being forced to shift to a specialised concrete supplier. Adding carbon dioxide has also proven to improve concrete compressive strength by 12% over a reference mix.

Steel has significant carbon impacts, but low-carbon or green steel created from renewable or electric arc furnaces is available. Although the automotive industry is currently driving demand for green steel, it’s a material whose availability is predicted to grow at an 85.8% compound annual growth rate in the next 10 years.

We use a calculation tool, OneClick, that helps owners see the impact of carbon in materials. It separates project materials into non-sequestering and sequestering, illustrating the carbon impact of material choices which we can then portray in a format like the Sankey diagram shown here.

By viewing these factors of embodied carbon footprint and life cycle operations holistically, a design team and owner can make more informed sustainability decisions during design. Orange County Sanitation District fully embraced this sustainable design thinking for their headquarters complex and made innovative use of mass timber as described above.

3. Reducing Energy Loads Through Building System Design

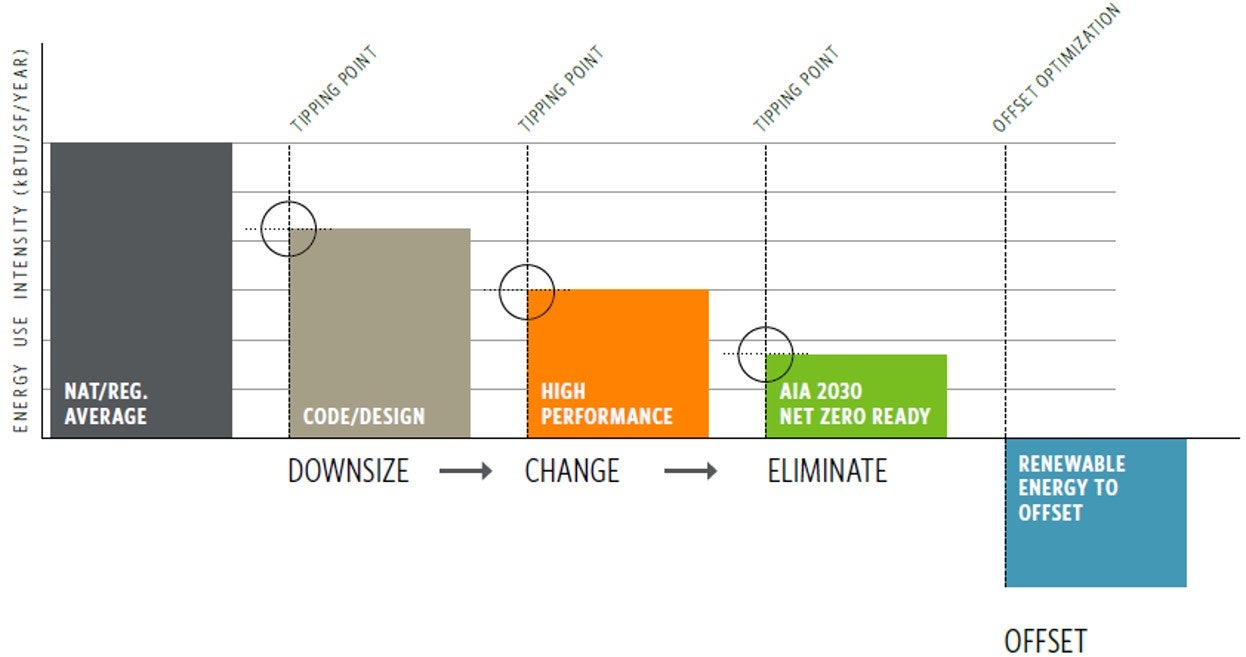

Achieving a decarbonised building design requires an approach that prioritises energy efficiency from the start rather than relying on an array of bolt-on renewable devices.

We focus on the “tipping points” phenomenon — as loads are reduced, the supporting systems get smaller and more efficient to maintain.

Downsize

The first tipping point is to assess and reduce energy loads — or “downsize.” For example, the impact of having large, windowed areas can be controlled by using shades from appropriate angles. We can use historical and future climate projection weather files to model solar irradiance. Dynamic glazing on windows can tint automatically as radiation changes and switchable smart glass, in fully opaque mode, can reduce by 40% the amount of heat entering the building. Future climate projection weather files can analyse the climate change resiliency and adaptability of the building design as temperatures rise and surface radiation increases. A net zero building designation isn’t just for the ribbon cutting day — it also looks at the total life cycle of the building. An effective design addresses adaptable operations — the ideal operation range that is expected now in addition to normal operation years from now.

Change

Next, we optimise the systems we are using — addressing the “change” tipping point. For example, airport terminals typically have high ceilings. Comfort delivery systems using displacement ventilation are well suited to such spaces because they deliver conditioned low-velocity air directly into the occupied zone. Instead of typical overhead systems which deliver conditioned high-velocity air and rely on “throwing” air long distances, displacement ventilation results in reduced fan energy, lower heating/cooling consumption and increased air distribution effectiveness, all resulting in significant system efficiencies.

Another “change” strategy is to look at DC, or direct current, lighting. DC power generated from renewable sources is normally converted to AC, or alternating current, via an inverter for standard building uses, but that results in energy losses during conversion. LED fixtures illustrate this inefficiency; they are essentially DC lights with a small built-in AC to DC inverter. So to power LED lights through DC-generated solar power, facilities are converting from DC to AC and then back to DC — with both conversions resulting in inefficiencies. Commercial buildings, including airport terminals, can be designed to use solar power via DC to drive LED fixtures, resulting in more efficiency, overall lower system costs, less infrastructure and less maintenance.

Eliminate

Finally, the third tipping point “eliminates” all fossil fuel combustion. Buildings that are designed to be all-electric eliminate on-site air quality issues associated with fossil fuels, such as harmful byproducts and PM2.5 particulates, and efficiently use on-site generated electricity from renewable energy systems. Renewable energy can be directly used year-round with the incorporation of on-site building energy storage system.

Backup and standby power systems, historically powered by diesel generators, can instead be powered by renewable energy sources because of recent changes to National Fire Protection Association code. Building energy storage systems and fuel cells can be used as backup/standby power when such systems meet startup/changeover time thresholds.

An all-electric building without offsetting renewables is not yet zero emission today, because the U.S. power grid is still heavily dependent on fossil fuels, but as the grid decarbonises, all-electric buildings can become net zero.

Heat pumps and geo-exchange systems are key technologies to consider when eliminating fossil fuels. Heat pumps’ advantage is that they are an efficient means of generating heat via an all-electric source. In the cooling season, heat is removed from a space and transferred to the atmosphere, ground or water-source, whereas in the heating season, heat is extracted from the atmosphere, ground or water-source and delivered to the occupied space. Air source pumps, which use the atmosphere as a heat source/sink, have the most flexibility and adaptability, but are less effective at outside air temperatures below 40 degrees Fahrenheit. Heat pumps using ground or water heat source/sinks provide additional operating range during lower outside air temperatures.

Geoexchange or geothermal systems are increasingly embraced by airports; Vancouver and Louisville are both incorporating geothermal systems that use the relatively constant temperatures of the below-grade earth as a heat source/sink in combination with heat pumps to generate heating and cooling. Typically configured geoexchange vertical borefields (400-600 feet depth) are best suited for airport projects as they can be installed underneath parking lots, parking garages, vegetated open spaces, as well as numerous low-weight-intensity plane-side hardscapes. Excess heat stored in a geoexchange system can, for example, be used to power radiant heating in under-the-wing support spaces to keep floors drier, reduce slipping, and reduce snow plowing needs.

4. Use Renewable Energy Sources

Solar power or photovoltaics is the most obvious renewable energy source. While ground-mount and rooftop-mounted photovoltaic systems are the industry standard, building integrated photovoltaics, wherein photovoltaic modules are installed on the building surfaces, offer significant opportunities for renewable energy generation. BIPV create collateral benefits such as allowing views in and out, shading users from direct sun, and creating exciting shadow patterns on the interiors. Analysis on the massing/form in the early design stages of a project can identify building surfaces that have generation potential. BIPV can even be integrated into a rear ventilated rain screen wherein they clad the solar cells with a transparent façade surface, which maintains the building aesthetics while being highly efficient and functional.

Renewable systems, specifically solar photovoltaic systems, also need to be designed to assure that the net zero designation is maintained over the course of the building life cycle. Photovoltaic modules experience solar degradation, losing output capacity over time due to environmental condition exposure. A typical module manufacturer warranty states that a photovoltaic module will lose 20% of its output capacity over 25 years. Owners must take this degradation into account when designing a net zero building.

Solar hydrogen or green hydrogen is another promising energy source being adopted by commercial, industrial and healthcare facilities and appropriate to airport facilities. Stored hydrogen — generated by a solar photovoltaic array — becomes the site’s "battery” that, when needed, is fed through a hydrogen fuel cell to provide power. Green hydrogen systems will evolve in the short term as manufacturers of electrolysis units (which convert water into hydrogen gas and oxygen) and hydrogen fuel cell units (which convert hydrogen gas into power with a byproduct of water vapor) develop the means to recover the water vapor byproduct and re-use it as the water source for the electrolysis unit for a true closed-loop zero-loss water circuit.

We’re developing a tool based on a theoretical zero energy solar hydrogen hospital in Omaha, Nebraska, and talking with a pharmaceutical company who’s interested in solar hydrogen. The tool identifies the necessary equipment capacities for a viable on-site solar hydrogen system, including a photovoltaic array, electrolysis units, gas compressors, hydrogen storage tanks and hydrogen-based fuel cells. Tank capacity is particularly important given seasonal solar generation variability. The right size tanks will allow airports to store excess hydrogen during peak irradiance hours (summer) for use during darker periods of the year (winter). Hydrogen tanks need to be placed on a property away from buildings for safety reasons but, given airports’ existing fuel-handling and safety protocols, this is not a barrier to adoption. Our research and development investment in this model will be applied across building sectors for space planning and to size the tanks, fuel cells and supporting infrastructure.

Kinetic floor tiles are a very intriguing new technology being tried in retail, education, smart cities, and transportation. They capture the physical or kinetic energy generated when people walk upon the tiles. While only a small amount of energy is generated — enough to power lights or monitors in the area — their use demonstrates to travellers an airport’s commitment to sustainability while leaving a lasting impression of innovative clean energy generation.

Useful Strategies Come from All Building Types

Airports around the world are at various points in their progress toward achieving FAA and IATA sustainability goals. Whether we’re designing a completely new facility or upgrading portions of an existing terminal, ideas for optimising form and function, reducing energy loads, and using sustainable materials and renewable energy all contribute toward sustainable terminal design.

Buildings of all types — from healthcare and public buildings to industrial to transportation facilities — provide vital lessons and strategies for all vertical infrastructure’s journey toward carbon neutrality. The movement toward net zero airport terminals is an example of what is possible at an airport — a very public and recognisable segment of our infrastructure.